CYS compressed air high efficiency oil water separator

CYS compressed air high efficiency oil water separator

This series of high-efficiency oil-water separator is a new generation of compressed air secondary purification (gas-water separation and filtration) device newly developed by our company. It has good technical performance and wide applicability. It can be installed after compressor, aftercooler, freezing dryer, adsorption dryer, or on the main pipeline of general industrial gas. It can effectively separate and filter the pollutants (oil, water, dust) in the compressed air.

Technical Indicators

Air handling capacity: 1-500nm3 / min

Working pressure: 0.6-1.0mpa (1.0-3.0mpa products can be provided according to user requirements)

Air inlet temperature: ≤ 50 ℃ (min 5 ℃)

Filter aperture: ≤ 5 μ M

Residual oil content: ≤ 1ppm

Vapor liquid separation efficiency: 98%

Pressure drop of inlet and outlet air: ≤ 0.02MPa

Ambient temperature: ≤ 45 ℃

Filter element: filter material imported from British DH company

Service life: ≥ 8000h

Working Principles

CYS is mainly composed of vessel parts, spiral separator, filter element parts, instrument and automatic blowdown device. The compressed air containing a large amount of oil and water and solid particles enters the spiral channel of the spiral separator tangential after the variable diameter acceleration. Most of the liquid drops and large particles are shaken off by the centrifugal effect. The compressed air after pretreatment can only enter the inner cavity of the spiral separator due to the obstruction of the intermediate tray, and passes through the cartridge filter element from the outside to the inside. Further capture tiny foggy particles, generate condensation and realize gas-liquid separation away.

Technical Parameters

|

Model / parameter name |

CYS-1 |

CYS-3 |

CYS-6 |

CYS-10 |

CYS-15 |

CYS-20 |

CYS-30 |

CYS-40 |

CYS-60 |

CYS-80 |

CYS-100 |

CYS-120 |

CYS-150 |

CYS-200 |

CYS-250 |

CYS-300 |

|

Air Flow (Nm3/min) |

1 |

3 |

6 |

10 |

15 |

20 |

30 |

40 |

60 |

80 |

100 |

120 |

150 |

200 |

250 |

300 |

|

Air pipe diameter |

DN25 |

DN32 |

DN40 |

DN50 |

DN65 |

DN65 |

DN80 |

DN100 |

DN125 |

DN150 |

DN150 |

DN150 |

DN200 |

DN200 |

DN250 |

DN300 |

|

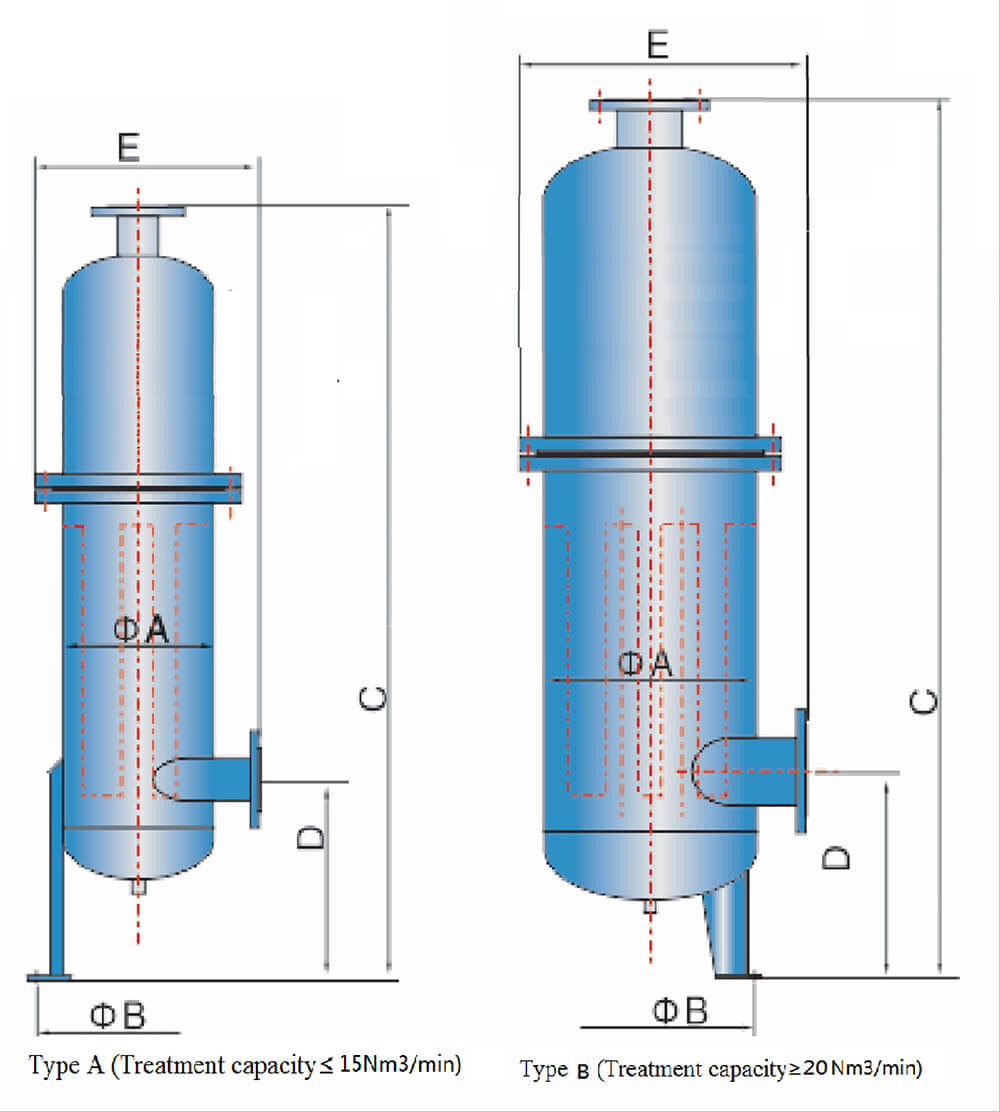

Tube diameterΦA(mm) |

108 |

108 |

159 |

159 |

273 |

219 |

325 |

325 |

362 |

412 |

462 |

512 |

562 |

612 |

662 |

716 |

|

Anchor bolt diameterΦB(mm) |

190 |

130 |

252 |

314 |

314 |

388 |

440 |

440 |

350 |

400 |

450 |

500 |

538 |

600 |

650 |

700 |

|

Total height C(mm |

609 |

1587 |

744 |

1035 |

1175 |

1382 |

1189 |

1410 |

1410 |

1424 |

1440 |

1487 |

1525 |

1614 |

1631 |

1660 |

|

High import D(mm) |

408 |

280 |

410 |

350 |

350 |

403 |

416 |

416 |

410 |

425 |

441 |

476 |

520 |

605 |

641 |

661 |

|

Width E(mm) |

238 |

212 |

273 |

360 |

360 |

414 |

485 |

485 |

534 |

589 |

634 |

691 |

741 |

771 |

871 |

923 |

|

Net weight of equipment (kg) |

25 |

30 |

50 |

75 |

85 |

92 |

105 |

135 |

150 |

195 |

230 |

240 |

260 |

310 |

352 |

425 |