CWD Compressed air low pressure steam blast regeneration zero gas consumption dryer

CWD Compressed air low pressure steam blast regeneration zero gas consumption dryer

The steam heated air blast regeneration adsorption dryer is a kind of adsorption dryer developed by absorbing the advantages of the thermal adsorption regeneration dryer and the non thermal regeneration adsorption dryer.

Technical index

|

attribute |

working pressure |

Inlet temperature |

ambient temperature |

Cycle period |

Regeneration gas consumption |

Dew point temperature |

Power Supply |

|

parameter |

≤0.2MPa -0.5MPa |

≤45℃ |

-20~50℃ |

8ht |

0% |

-40℃-60℃ |

3φ-380V50Hz |

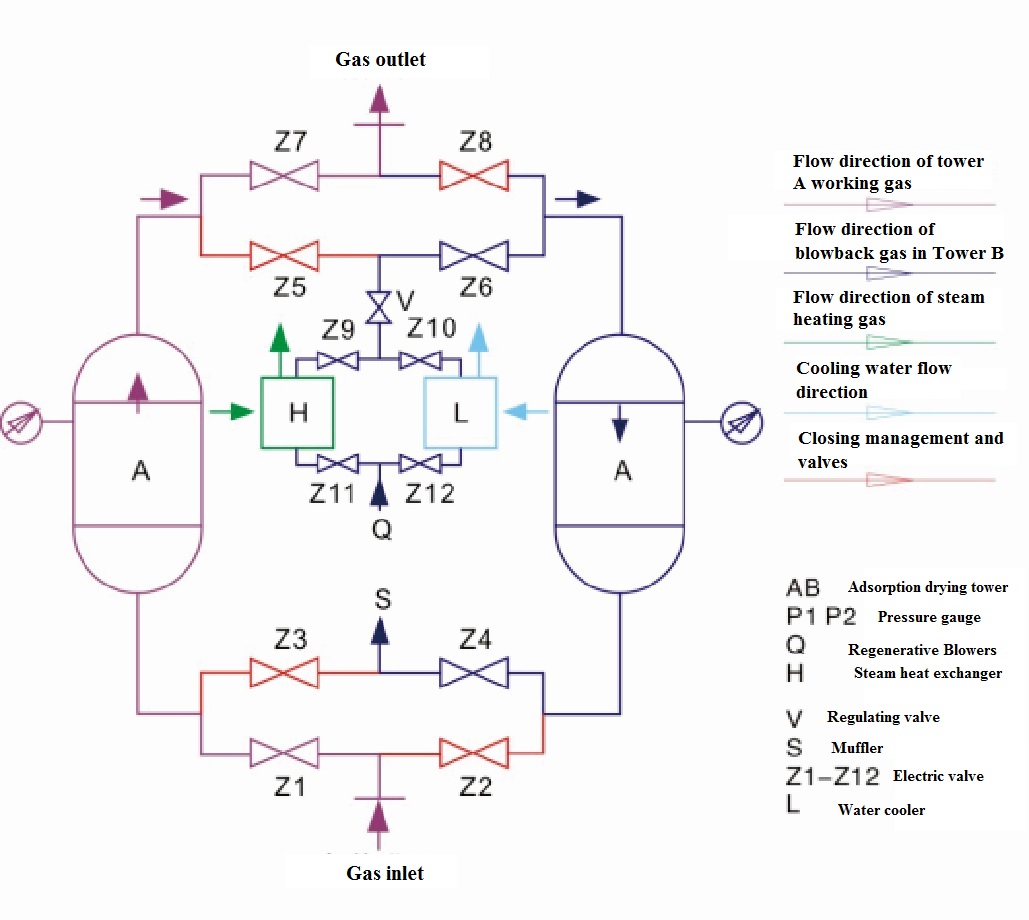

Working Principles

The utility model adopts steam heating blast to regenerate the desiccant, thus avoiding the disadvantages of short switching time and large regeneration gas consumption of the heatless regeneration adsorption dryer, as well as the disadvantages of large power consumption of the heatless regeneration adsorption dryer. The steam heated air blast regeneration dryer uses high temperature steam to heat the air blast, purge and regenerate the desiccant of the dryer, then use the water cooler to cool the air blast, and cold blow the desiccant of the dryer to improve the utilization efficiency of the desiccant, so as to improve the regeneration effect and achieve the goal of zero gas consumption.