CPN-M membrane separation nitrogen generation equipment

CPN-M membrane separation nitrogen generation equipment

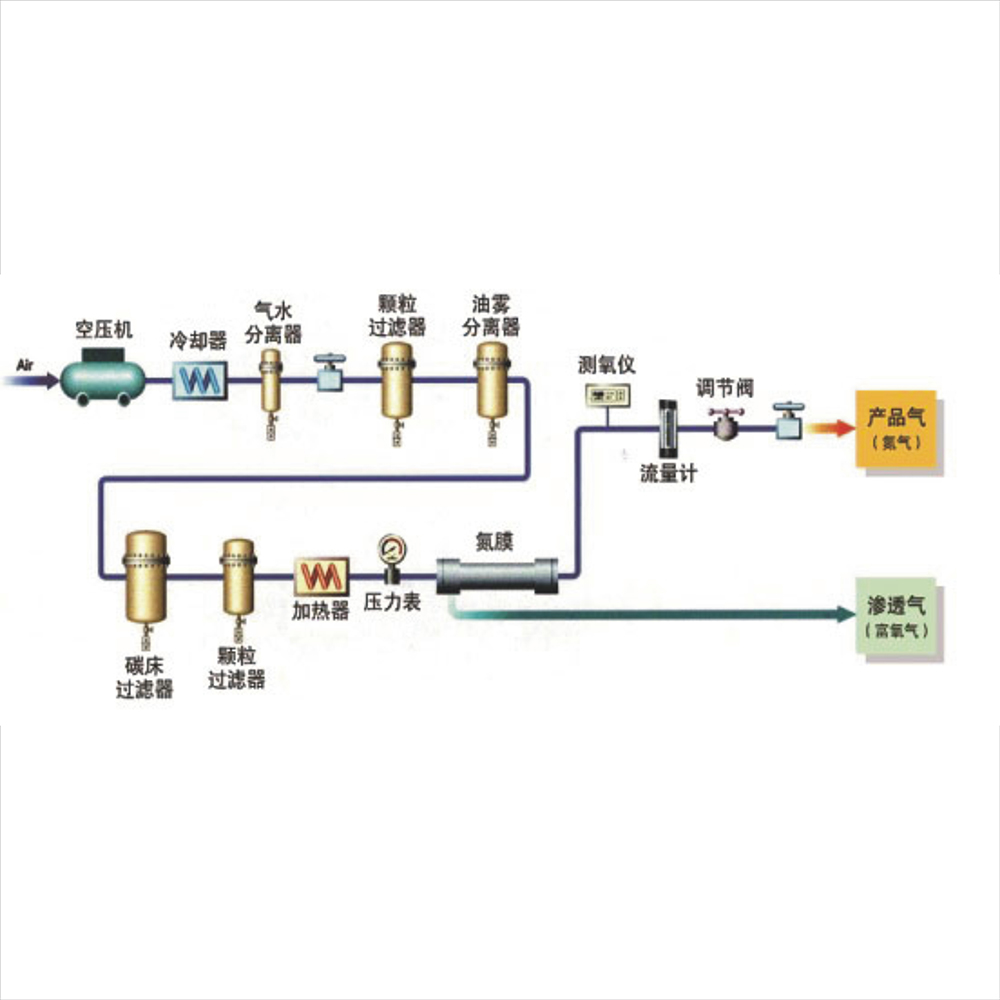

Membrane separation is one of the most advanced air separation technologies in the world. The principle is to achieve the purpose of nitrogen and oxygen separation by using the difference of permeation rate of each component gas in the air passing through the separation membrane. The schematic diagram is shown on the right:

Advantages of nitrogen making membrane

◎The separation membrane is made of the most advanced polyimide (PI) hollow fiber.

◎Wide temperature range of separation membrane: 3-90 ℃.

◎Wide range of operating pressure: 0.3MPa ~ 10MPa.

◎High separation coefficient, large gas volume and high recovery.

◎Good chemical and physical stability.

◎Long service life, generally up to 10 years.

◎High efficiency, low cost, small volume and light weight.

◎The purity of nitrogen can be adjusted by 90% – 99.9%.

◎Strong adaptability to ambient temperature: – 20 ~ 45 ℃

Application Area

Oil and natural gas: oil and natural gas drilling construction; natural gas and coalbed methane production from tank and oil tank sealing; offshore platform application; oil well protection tertiary oil production

Transportation: protective gas during transportation of inflammable and explosive dangerous goods

Chemical / light industry: inert protection during replacement, purging and sealing; plastic and rubber anti-oxidation; chemical warehouse and dangerous goods protection

Heat treatment: annealing, carburizing, quenching, welding and other protective gases

Agriculture and catering industry: fruit storage, vegetable preservation, grain pest control

Coal / storage: fire fighting, explosion-proof; protective gas in the process of gas transportation and packaging

Medicine: protective gas during covering, nitrogen sealing, gas transportation and packaging

Protection of Cultural Relics: fire protection and oxidation protection of cultural relics

Technical parameters of CPN95-M type membrane nitrogen production (95%N2)

|

Model and specification |

N2 production(N㎥/h) |

Effective gas consumption(N㎥/min) |

Air purification system |

|

CPN95-M-60 |

60 |

2.1 |

QJ-3 |

|

CPN95-M-100 |

100 |

3.55 |

QJ-6 |

|

CPN95-M-150 |

150 |

5.3 |

QJ-6 |

|

CPN95-M-200 |

200 |

7.1 |

QJ-10 |

|

CPN95-M-300 |

300 |

10.6 |

QJ-12 |

|

CPN95-M-400 |

400 |

14.2 |

QJ-20 |

|

CPN95-M-600 |

600 |

21.2 |

QJ-30 |

|

CPN95-M-800 |

800 |

28.4 |

QJ-30 |

|

CPN95-M-1000 |

1000 |

35.5 |

QJ-40 |

|

CPN95-M-1200 |

1200 |

42.3 |

QJ-50 |

|

CPN95-M-1500 |

1500 |

52.7 |

QJ-60 |

Technical parameters of CPN39-M type membrane nitrogen production (99.9%N2)

|

Model and specification |

N2 production(N㎥/h) |

Effective gas consumption(N㎥/min) |

Air purification system |

|

CPN39-M-5 |

5 |

0.93 |

QJ-1 |

|

CPN39-M-10 |

10 |

1.85 |

QJ-3 |

|

CPN39-M-20 |

20 |

3.70 |

QJ-6 |

|

CPN39-M-30 |

30 |

5.56 |

QJ-6 |

|

CPN39-M-60 |

60 |

11.1 |

QJ-12 |

|

CPN39-M-80 |

80 |

14.8 |

QJ-20 |

|

CPN39-M-100 |

100 |

18.5 |

QJ-20 |

|

CPN39-M-150 |

150 |

27.8 |

QJ-30 |

|

CPN39-M-200 |

200 |

37.0 |

QJ-40 |

|

CPN39-M-300 |

300 |

55.6 |

QJ-60 |

Note:

1. The data listed in the above table are based on the design basis of raw compressed air pressure of 1.3mpa (gauge pressure), air inlet temperature ≤ 38 ℃, ambient temperature of 38 ℃, 1 standard atmospheric pressure and 80% relative humidity;

2. When the model or design conditions not mentioned in the above table are changed, please consult our company for details of the equipment.