CCD Compressed air combined low dew point dryer

CCD Compressed air combined low dew point dryer

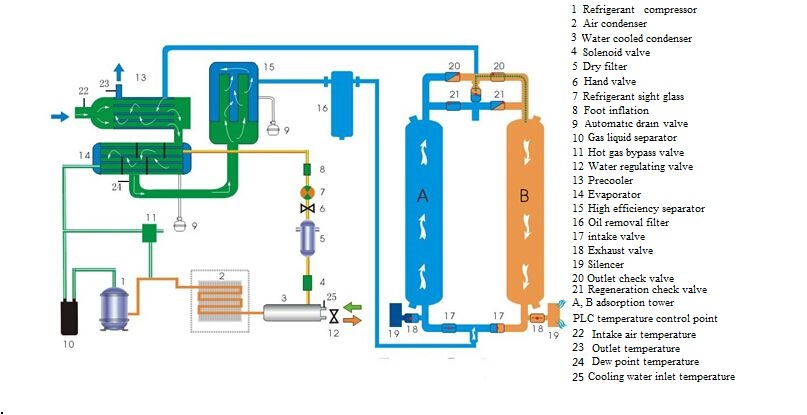

The combined dryer is mainly composed of the freezing dryer and the adsorption dryer, sometimes with the corresponding filtration, dust removal, oil removal and other devices, so that the dryer can adapt to more complex gas environment.

Technical Indicators

Air handling capacity: 1-500N㎥ / min

Working pressure: 0.6-1.0mpa (1.0-3.0mpa products can be provided according to user requirements)

Air inlet temperature: normal temperature type: ≤ 45 ℃ (min5 ℃)

Cooling mode: high temperature type: ≤ 80 ℃ (min5 ℃)

Air / water cooled

Dew point of product gas: - 40m ℃ ~ 70 ℃ (atmospheric dew point)

Pressure drop of inlet and outlet air: ≤ 0.03mpa

Working Principles

The filter, which integrates three-stage purification of cyclone separation, ancestral filtration and fine filtration, directly blocks the oil and water in the compressed air. Through cyclone separation, sedimentation, coarse filtration and dysprosium filter layer filtration, the oil, water and dust in the compressed air can be completely removed.

Technical Features

●The refrigeration and dehumidification, cyclone wind separation and other processes are adopted for the cold dryer. Pressure swing adsorption, temperature swing adsorption and other processes are used in the dryer. If there are corresponding filtering, dedusting, degreasing and other devices, there are direct interception, inertial collision, gravity settlement and other filtering treatment.

● The operation is stable and reliable, and the regeneration heat source can be operated unattended for a long time (there is micro heating in the dryer part). The electric heating regeneration step is heating + cooling.

● It uses its own dry air as the regeneration gas source with low gas consumption.

●Long cycle switching: automatic operation, unattended operation.

●The components of the refrigeration system are reasonably configured with low failure rate.

● Adopt electronic intelligent or floating ball type automatic blowdown device to realize automatic blowdown function.

● The process flow is simple, the failure rate is low, and the investment cost is low.

● It is easy to operate and maintain.

●It has simple electrical automation operation, main operation parameter indication and necessary fault alarm.

●The whole machine leaves the factory, and there is no foundation installation in the room: the pipeline is installed in pairs.

Technical index

| Model

Project |

CCD-1 |

CCD-3 |

CCD-6 |

CCD-10 |

CCD-12 |

CCD-15 |

CCD-20 |

CCD-30 |

CCD-40 |

CCD-60 |

CCD-80 |

CCD-100 |

CCD-150 | CCD-200 | CCD-250 | CCD-300 | ||

| Air handling capacity(N㎥/min) |

1 |

3.8 |

6.5 |

11 |

12 |

17 |

22 |

32 |

42 |

65 |

85 |

110 |

160 |

200 |

250 |

300 |

||

| Power Supply | AC220V/50Hz |

AC380V/50Hz |

||||||||||||||||

| Compressor power(KW) |

0.28 |

0.915 |

1.57 |

1.94 |

1.7 |

2.94 |

4.4 |

5.5 |

7.35 |

11.03 |

14.7 |

22.05 |

30 |

23 |

28 |

36 |

||

| Air nozzle diameter DN(mm) |

25 |

25 |

40 |

50 |

50 |

65 |

65 |

80 |

100 |

100 |

100 |

150 |

200 |

200 |

250 |

250 |

||

| Diameter of cooling water pipe (water cooling) |

- |

- |

G1/2" |

G3/4" |

G3/4" |

G1" |

G1" |

G1½" |

G1½" |

G1½" |

G2" |

G2" |

G2" |

G3" |

G3" |

G3" |

||

| Cooling water quantity (water cooling m3/h) |

- |

- |

1 |

1.6 |

1.9 |

2.4 |

3.2 |

4.8 |

6.3 |

9.5 |

12.7 |

15.8 |

23.6 |

31.5 |

39.3 |

47.1 |

||

| Fan power (air cooling, w) |

100 |

90 |

120 |

180 |

290 |

360 |

360 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||

| Desiccant is important(kg) |

40 |

70 |

110 |

165 |

185 |

265 |

435 |

580 |

700 |

970 |

1660 |

1950 |

2600 |

3200 |

3710 |

4460 |

||

| Electric heating power (micro heat, kW) |

1.5 |

1.5 |

1.9 |

2.5 |

2.5 |

4.5 |

7.5 |

11.4 |

15 |

20.4 |

30.6 |

40.8 |

60 |

72 |

84 |

96 |

||

| Dimensions(mm) | Length |

900 |

960 |

1070 |

1230 |

1450 |

1600 |

1700 |

1900 |

2100 |

2650 |

2750 |

3000 |

3500 |

4160 |

4300 |

4500 |

|

| Width |

790 |

1300 |

1450 |

1700 |

1250 |

1960 |

2070 |

2460 |

2810 |

3500 |

3700 |

4380 |

4650 |

2890 |

2950 |

2950 |

||

| Height |

1100 |

2200 |

2040 |

2180 |

1850 |

2360 |

2410 |

2820 |

2840 |

2890 |

2990 |

3305 |

3420 |

3200 |

3400 |

3800 |

||

| Equipment weight(kg) |

300 |

270 |

540 |

680 |

1200 |

1300 |

1390 |

1960 |

2340 |

3400 |

4380 |

6430 |

9050 |

13100 |

14500 |

15200 |

||